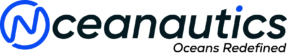

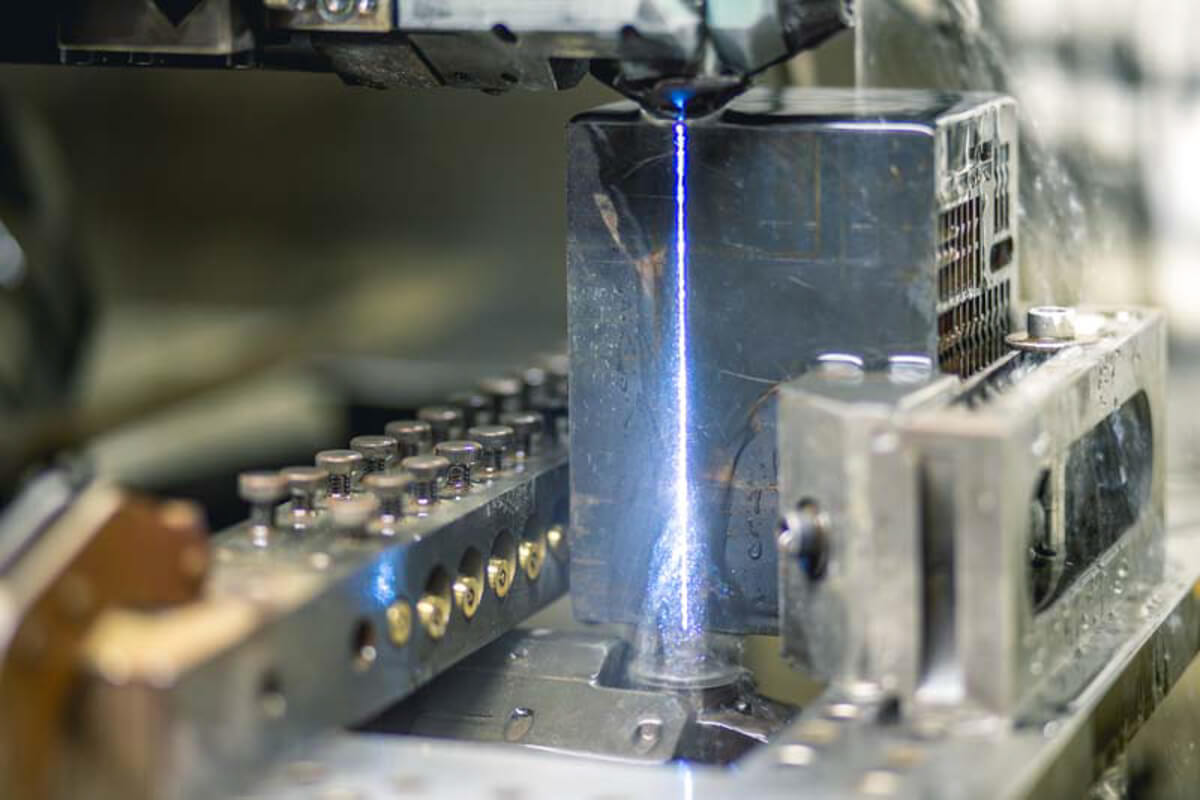

ELECTRICAL DISCHARGE MACHINING (EDM)

Electrical discharge machining (EDM), also known as spark machining, spark eroding, die sinking, wire burning, or wire erosion, is a metal production method that involves the use of electrical discharges to achieve a desired shape (sparks). A series of quickly recurring current discharges between two electrodes separated by a dielectric liquid and subjected to an electric voltage remove material from the work piece. The tool-electrode, or simply the tool or electrode, is one of the electrodes, while the workpiece-electrode, or work piece, is the other. The tool and the work item must not make physical touch for the process to work.