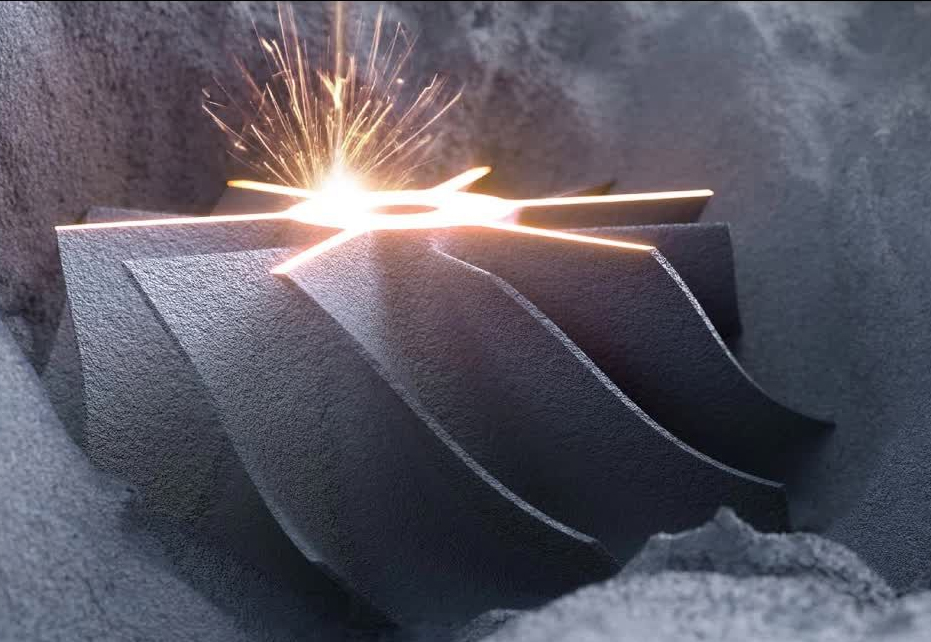

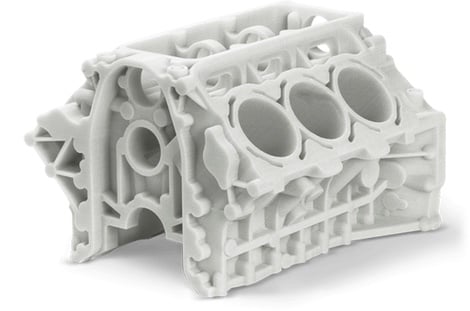

SELECTIVE LASER SINTERING (SLS)

One of the most widely used prototyping technique for functional parts and components due to its ability to create complex geometries very easily. Accurate prototypes and functional production parts with high durability, using multiple nylon based powders.