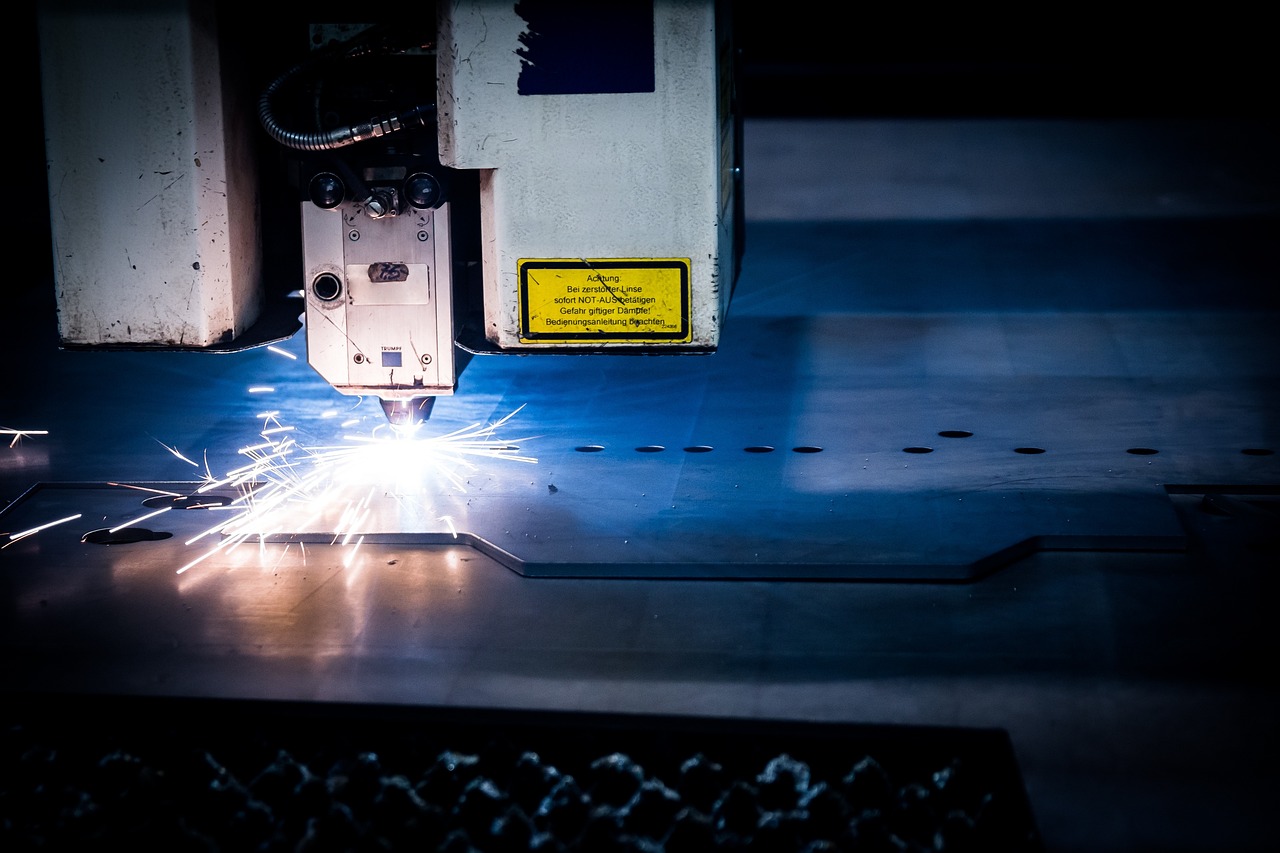

LASER CUTTING

Laser cutting is a technique that involves vaporizing materials with a laser to create a cut edge. It is now utilized by small enterprises, architects, and amateurs. It was originally designed for industrial production purposes. Laser cutting works by directing the output of a high-power laser through optics, which is the most frequent method. The laser beam created is directed using laser optics and CNC (computer numerical control).