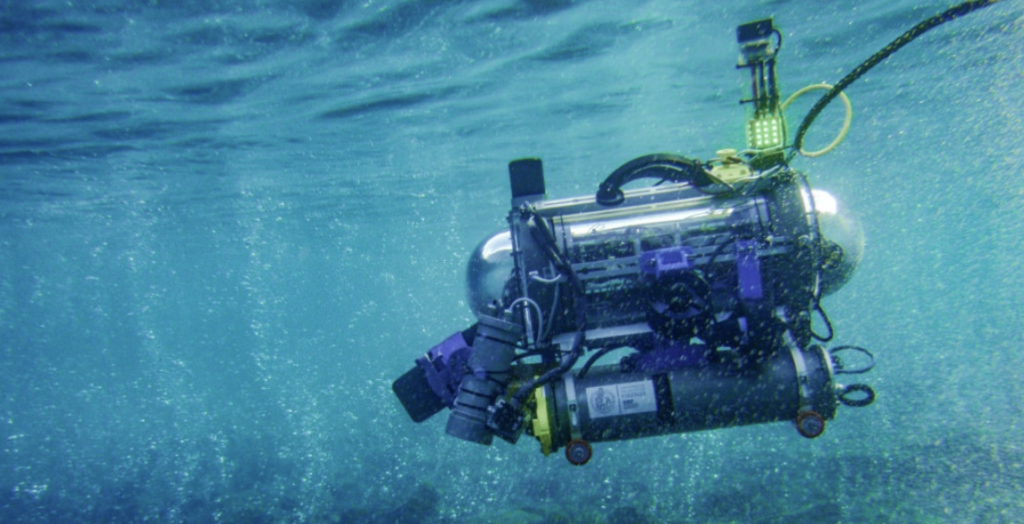

ROV, AUV, & Underwater Drone Thruster Applications

The T200 Thruster is used on a number of underwater ROVs, AUVs, and underwater drones including our flagship underwater ROV, the BlueROV2. The thrusters provide compact but powerful underwater propulsion on the ROV.

The thrusters are also used on AUV platforms such as the RangerBot from QUT and many others, making autonomous underwater robotics an affordable possibility for researchers, scientists, and businesses.

The T200 Thruster powers a number of underwater drones designed to inspect, explore, and film underwater infrastructure, ships, aquaculture pens, and shipwrecks.

Thruster Technology

The T200 Thruster uses our patented underwater thruster design consisting of a fully-flooded brushless motor with encapsulated motor windings and stator as well as coated magnets and rotor. The thruster body and propeller are made from tough polycarbonate plastic and the only exposed metal components are made from marine grade 316 stainless steel.

The fully-flooded design is unique compared to thrusters existing before the T200. It allows the motor to be water-cooled and the plastic bushings to be water-lubricated. It eliminates the need for shaft seals, magnetic couplings, and air- or oil-filled compartments, making the thruster naturally pressure tolerant. The design is compact and has a minimal number of parts so that we can offer it at an affordable price.

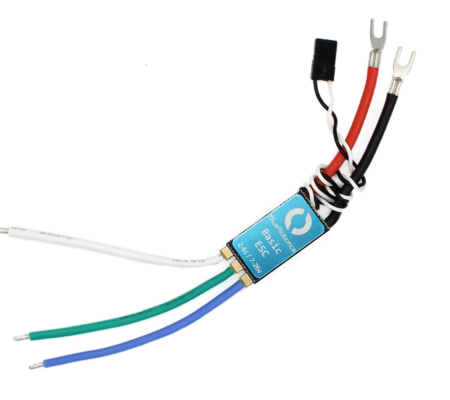

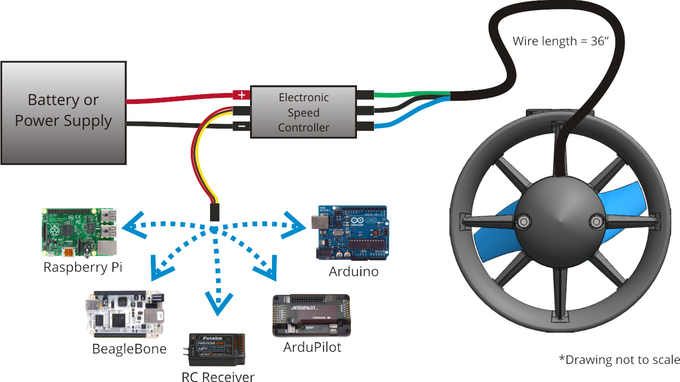

The core motor design is a three-phase brushless outrunner motor, similar to what you’d see on drones and RC airplanes, but optimized for underwater use. A sensorless brushless electronic speed controller (ESC) like our Basic ESC is required to run the thruster in all situations. It’s optimized to run at a voltage of 16v (such as a 4s lithium-ion battery pack), but can run at a range of voltages. Check out the detailed performance charts on the Technical Details tab for more information.

USVs, Kayaks, and SUPs Thruster Applications

The T200 Thruster can propel robotic unmanned surface vessels (USVs) and flexible mounting options make it easy to turn just about anything that floats into a USV! We’ve seen it used on anything from a boogie board to a commercial-grade survey vessel.

Combined with a battery, ESC, and the Thruster Commander, it’s easy to use on a kayak or stand-up paddleboard (SUP) as well! Two T200s on a paddleboard will get it moving at over 3 knots!

MATE, RoboSub, and Robotics Competition Applications

In addition to commercial and research applications, the T200 Thruster is the thruster of choice for MATE ROV competitions, the RoboSub AUV competition, and other competitions including RoboBoat, European Robotics League (ERL), and the Singapore AUV Challenge (SAUVC). The T200 provides an affordable and reliable thruster option to replace the bilge pump motors and expensive thrusters used in the past.

Using the T200 Thruster

The T200 Thruster comes ready to use and includes both clockwise and counterclockwise propellers. In addition to the thruster, you need a speed controller like our Basic ESC, a power source like our battery, and a signal source, such as our Thruster Commander, an RC radio receiver, or a microcontroller like the Arduino or Raspberry Pi.

There is a wealth of available technical information, charts, code examples, and tutorials on the Technical Details and Learn sections of this page as well as support through our online forum community. There you can find users doing all sorts of interesting things ranging from generative ROV design to freediving jet boots to lionfish hunting robots!

We’re excited to see what you do with it!

Contents

- 1 x T200 Thruster

- 1 x Clockwise and counterclockwise propeller

Specifications

| Parameter | Value | |

|---|---|---|

| Performance | ||

| Full Throttle FWD/REV Thrust @ Nominal (16 V) | 5.25 / 4.1 kg f | 11.6 / 9.0 lb f |

| Full Throttle FWD/REV Thrust @ Maximum (20 V) | 6.7 / 5.05 kg f | 14.8 / 11.1 lb f |

| Minimum Thrust | 0.02 kg f* | 0.05 lb f* |

| Electrical | ||

| Operating Voltage | 7-20 volts | |

| Full Throttle Current @ Nominal (16 V) | 24 Amps | |

| Full Throttle Current @ Maximum (20 V) | 32 Amps | |

| Full Throttle Power @ Nominal (16 V) | 390 Watts | |

| Full Throttle Power @ Maximum (20 V) | 645 Watts | |

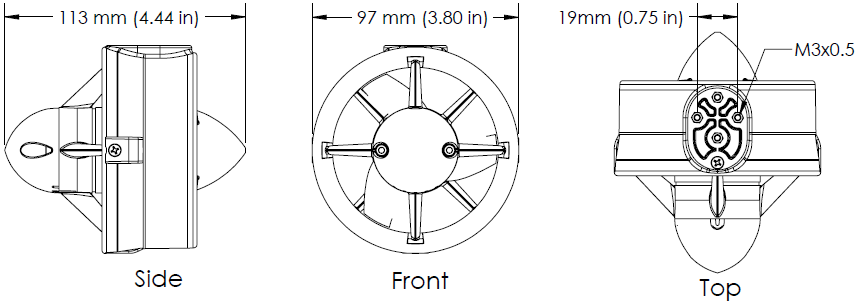

| Physical | ||

| Length | 113 mm | 4.45 in |

| Diameter | 100 mm | 3.9 in |

| Weight in Air (with 1m cable) | 344 g | 0.76 lb |

| Weight in Water (with 1m cable) | 156 g | 0.34 lb |

| Propeller Diameter | 76 mm | 3.0 in |

| Mounting Hole Threads | M3 x 0.5 | |

| Mounting Hole Spacing | 19 mm | 0.75 in |

| Cable | ||

| Cable Used | CAB-PUR-3-16AWG-R2 | |

| Cable Length (Standard T200) | 1.0 m | 39 in |

| Cable Length (T200 BlueROV2 Spare) | 0.71 m | 28 in |

| Conductor Gauge | 16 AWG | |

| Compatible WetLink Penetrator | WLP-M10-6.5MM-LC | |

*Values limited by ESC used to drive thruster.

Note that nominal operation at 12-16 V is recommended for the best balance of thrust and efficiency, though operation at up to 20 V is allowable. Exceeding 20 V is not within the rating and is not recommended, please see here for more information.

For more detailed performance specifications, including thrust, RPM, power, and efficiency at various throttle levels and supply voltages from 10-20 V, please see the performance charts below.

Performance Charts

Click on the legend to hide or show the data set for each voltage. All the raw data and notes on the testing procedure used to generate these charts can be downloaded here:

T200-Public-Performance-Data-10-20V-September-2019 (.xlsx)

2D Drawings

3D Models

T200-THRUSTER-R1 (.zip)

Quick Start

- Connect motor wires to ESC and connect the ESC to power and a signal.

- Send a signal and the thruster will start spinning. That’s it.

Revision History

- 12 February 2021 | R2 – Initial Release | Changed thruster cable conductors from 18 AWG to 16 AWG

- 08 November 2019 | Changed stator from being epoxy coated to fully potted | Added cooling holes to propellers

- 15 September 2019 |Changed finish of polycarbonate components from glossy to matte

- 19 September 2014 | R1 – Initial Release

Important Notes

- Always practice caution when you’re working with electricity in water and with the spinning blades of the propeller. Keep body parts away from the thruster inlet and outlet to avoid injury.

- Do not operate the thruster for extended periods out of water. The bearings are lubricated by the water and vibration and noise will be greater when dry.

- Do not use thread-locking compounds like Loctite on any part of the thruster. It will damage the plastic and cause it to become brittle.

- The thruster can handle saltwater environments pretty well, but it does not get along with seaweed. Avoid sucking seaweed into the thruster to avoid damage.

Reviews

There are no reviews yet.